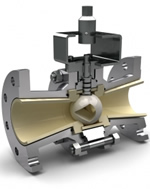

Ceramic Ball Valve

The ceramic valve typical applications for Silicon Powder,Alumina Powder,Dry Coal Powder,Limestone Slurry,Gypsum Slurry,Plaster,Fly Ash,Mining Ore,Coal Powder Injection,Metallurgical dust,Thermal Power plant FGD,Petroleum Solid Catalyst,TiO2 suspension with sulfuric acid,Ammonia solution with powder,Hydrochloric Acid,Liquid Chlorine,Bulk Material.

It’s well known that advanced ceramics materials, including high pure alumina, zirconia, solid tungsten carbide and silicon nitride, which can provide fundamental solutions to the corrosion and abrasion problems. Ceramic floating ball valves have excellent performance and much longer life time than soft seated and metal seated ball valves in most corrosive and abrasive applications.As a professional ceramic valve supplier, Komo supplies ceramic valves to meet these severe abrasive and/or corrosive applications.

Design Features:

→ Floating ball or trunnion ball

→ Ceramic fully lined

→ Corrosion resistant

→ Abrasion resistant

→ 3 Piece design option

→ Ceramic-to-ceramic spherical seated

→ V-port balls and round-port ball option

→ All kinds of valve type selection

→ Valve body material custom

→ Connection custom

→ Standard custom

→ Actuator option for bare stem valves, lever, pneumatic and electric control system

Ceramic Butterfly Valve

|

Ceramic Butterfly Valve

Flanged Type

Wafer Type

Lug Type

Actuator option for bare stem valves, lever, pneumatic and electric control system

|

Other Ceramic Valve

Ceramic Gate Valve

Ceramic Globe Valve

Ceramic Check Valve

|

Ceramic Pipe Fittings

Ceramic Lined Pipes

Ceramic Lined Tees

Ceramic Lined Pipe Elbows

Ceramic Lined Y Diverters

|