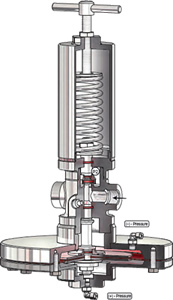

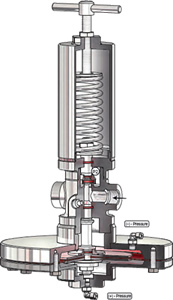

They are used to keep the differential pressure ΔP at a constant adjustable reference value at fluctuating primary pressures P1, fluctuating outlet pressures P2 or fluctuating flow volumes. Differential pressure control valves are based on pressure reducing valve and primary pressure control valve design and feature a closing function (closing on increasing differential pressure) or opening function (opening on increasing differential pressure).

In this case, the piston plate or membrane area is sealed off from the flow medium and the spring hood made pressure tight. The (+) pressure and the (-) pressure are directed by means of screw connections to one side of the piston plate or membrane. The (-) pressure must always be connected to the spring side.

Example:

(opens when differential pressure increases)

|

Nominal pressures : PN 1.6 to PN 16

Connections : G 1/4 to G 2 ½ or DN 10 to DN 100

Process connections : normal commercial thread, screw, clamp or flange connections

Materials : 1.4301, 1.4571, 1.4404, 1.4435, as well as elastomer

and thermo-plastic element seals

Primary pressure ranges P2 : 0.005 bars to max. 8 bars

Flow mediums : gases, vapours and fluids

|

Areas of application Differential pressure control valves:

1、Volume governor combined with a pressure transducer upstream to the valve.

2、 Flow governor combined with a pressure transducer located at another part of the system.

3、 Pressure controller for impulse reduction from another part of the system.

|

Example:

(closes when differential pressure increases)

|