Split Type Rupture Discs

Most technically advanced solution for low pressure aseptic and hygienic applications

It is an advanced reverse acting rupture disc, peripherally scored for accurate burst control. It has been designed with a smooth metal, uninterrupted surface finish to ensure its compatibility in CIP and SIP service. Designed for installation between ferrules and tri-clamps, this Ferrule is unique in being the only hygienic disc in the industry compatible with Komo’s non-invasive, ATEX-approved detection system. Combining technically advanced rupture disc capability with reusable burst detection makes this an obvious solution for many low pressure aseptic applications.

Offers unique benefits

Offers unique benefits

Where a very low burst pressure is required within a sanitary environment, Ferrule provides the highest performance characteristics available on the market. With a 95% operating ratio and 3% tolerance, the rupture disc combines the most technically overpressure protection in its field with ease and simplicity of installation. Integral to this design as standard is Komo’s reusable burst detection system, offering customers across the globe the added benefit of non-invasive identification of a disc burst.

Highest life cycle capability of any aseptic Rupture Disc

Specifically designed for low burst pressures, it is a non-fragmenting bursting disc, tested to over 100,000 pressure-vacuum cycles and is suitable for use in liquid, gas or vapour. Manufactured in Stainless Steel as standard with an FDA certified seal, this bursting disc is ideal for a range of applications within the food and beverage sectors, as well as the pharmaceutical and biotech industries.

Leading the industry in advanced quality standards

Leading the industry in advanced quality standards

• Designed specifically for low burst pressure applications

• Industry best 3% tolerance

• Non-fragmenting design

• Suitable for use with tri-clamps / ferrules

• Ideal for CIP/ SIP applications

• Supplied with Flo-Tel™ burst detection as standard

• FDA, 3A, USP certified

Sensor

Non-invasive ATEX approved burst detection.

Sensor is a non-invasive fail safe detection system providing an excellent solution for identifying when a rupture disc functions within arduous operating conditions. After rupturing the disc is the only element to be replaced, eliminating expensive re-wiring costs. it is complete with an inbuilt thermistor for process temperature monitoring when incorporated into the wireless Radio-Tel detection system.

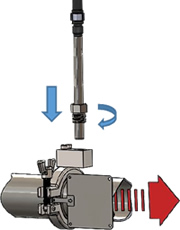

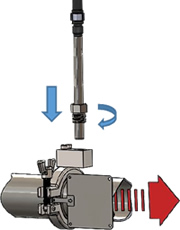

System Operation

Operating on simple reed switch and magnet technology, it is designed to offer a practical solution for rupture disc detection needs. The sensor is fitted into the holder with a magnet on the rupture disc. When the rupture disc bursts; the rupture disc with its magnet arc away from the sensor, giving an open circuit signal. After rupturing the disc is the only element that needs replacing.

• ATEX approved ExII 1GD EEx ia IIC. EC-Type Examination Certificate ITS03 ATEX 21698X, must be connected to an intrinsically safe supply.

• ATEX approved, thus able to operate in all levels of potential explosive atmospheres.

• Sensor is not in contact with the process therefore there are no potential leak paths.

• Non invasive design, therefore not affected by downstream pressure fluctuations or corrosion.

• IP 65 rated.

• Inbuilt thermistor provides data on the temperature of the process.