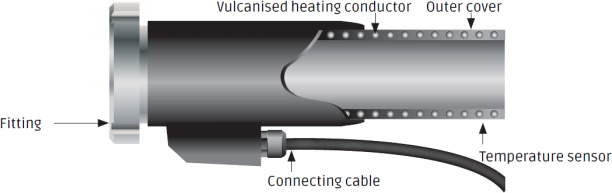

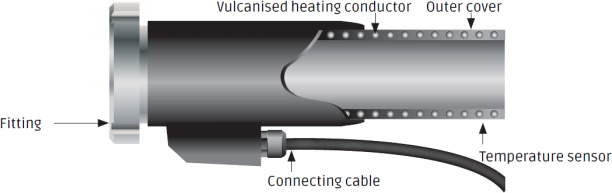

Heating hose with vulcanised heating conductor

Approval for foodstuffs

The foodstuffs hose stands out by virtue of its innovative construction. The heating element is spiral-wound on the NBR hose core and thus lies vulcanised in the inner hose material. This hose does no longer differs visibly or in its usage from an unheated hose, thus handling is simplified considerably. A temperature sensor is also integrated into the hose which measures temperature directly in the hose wall. Suitable for transporting fatty and non-fatty foodstuffs, as well as passing alcoholic and non-alcoholic beverages.

All the hose materials used meet the requirements (EC) no. 1935/2004 of the instructions from the Federal Institute for Risk Assessment (BfR) (Recommendation XXI, cat. 2) and FDA CFR § 177.2600 Approval for foodstuffs.

On request, we can also supply suction and pressure hoses with steel coil. Special hoses made of fluoropolymer (Viton) can be fabricated for higher temperatures. Connections with flanges, quick couplings or outer treads are also available on request.

A range of devices is available for temperature control. The line extends from the mini-controller with fixed temperature setting to convenient microprocessor controlled devices. See chapter Control technology.

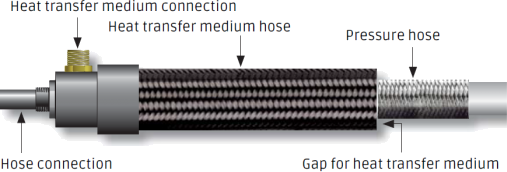

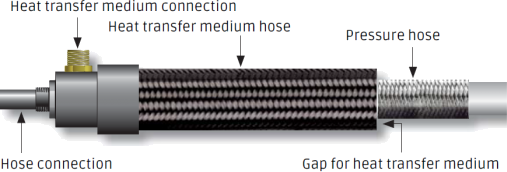

Double-jacket heating hose / heat transfer medium

|

Applications:

Explosion hazard areas.

Dosing equipment, food industry, filling lines.

The HDM hose can be used as a HEATABLE ELEMENT, as a COOLABLE ELEMENT and as a SAFETY ELEMENT.

A temperature regulating unit which works with steam, water or heat- transfer oil in a circulating system is required to operate HDM as a heating hose.

|

* The pressure specification is valid for the heat transfer medium in the outer hose when the inner hose is filled and is under operating pressure. There must be no negative pressure difference between the outer hose and the inner hose, i.e. the pressure in the inner hose must always be higher than in the outer hose. A negative pressure difference (e.g. during filling) can cause the inner hose to collapse. If a negative pressure difference is unavoidable, the inner hose can be provided with an outer jacket. The outer jacket distributes the pressure over the stainless steel braiding and prevents the inner core collapsing.

In the case of an integrated inner pressure hose T3, only use oil or another heat transfer media. No water! Braiding rusts!